News, Tin Tức, Tin tức bao bì tổng hợp

The Waterproof Advantage: Exploring Woven Polypropylene Bags

In the realm of packaging and storage solutions, woven polypropylene bags have emerged as a versatile and reliable option. Known for their durability, lightweight nature, and resistance to water, these bags have become a staple across various industries, including agriculture, construction, retail, and logistics. This article delves into the unique properties of woven polypropylene bags, their waterproof advantage, and the wide array of applications they serve.

Understanding Woven Polypropylene Bags

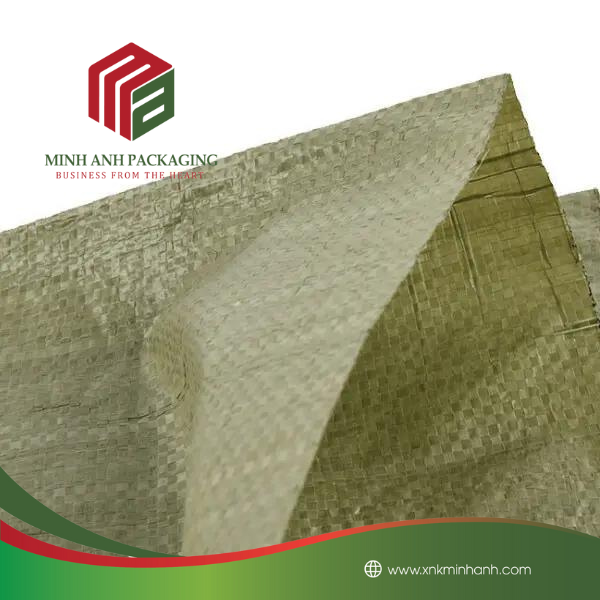

Woven polypropylene bags are crafted from polypropylene resin, a type of thermoplastic polymer. The resin is extruded into fibers or threads, which are then woven together to create a robust and flexible fabric. This woven structure provides the bags with exceptional strength and resilience, making them suitable for carrying heavy loads without tearing or breaking.

Polypropylene itself is known for its chemical resistance, low moisture absorption, and high melting point. These characteristics make it an ideal material for packaging applications where durability and environmental resistance are paramount.

The Waterproof Advantage

One of the standout features of woven polypropylene bags is their ability to resist water. While the woven structure allows for breathability, an additional lamination or coating can be applied to the fabric to achieve waterproofing. This lamination creates a barrier that prevents water from penetrating the bag, ensuring the contents remain dry and protected.

#Why Waterproofing Matters

Waterproof packaging is essential in numerous scenarios. For instance:

1. Agriculture: Farmers rely on woven polypropylene bags to store and transport grains, seeds, and fertilizers. A waterproof bag ensures that these materials are not damaged by moisture, which could compromise their quality or usability.

2. Construction: In construction, materials like sand, cement, and aggregates are often stored in polypropylene bags. Waterproofing prevents these materials from clumping or degrading when exposed to rain or humidity.

3. Logistics: During transportation, goods are frequently subjected to varying weather conditions. Waterproof woven polypropylene bags provide an added layer of protection against rain or accidental spills.

4. Retail: For products like pet food, animal feed, or powdered goods, maintaining dryness is crucial to preserving freshness and preventing spoilage.

#Lamination Techniques

The waterproofing of woven polypropylene bags is typically achieved through lamination. A thin layer of polypropylene film is fused onto the fabric’s surface, sealing the gaps between the woven threads. This process not only enhances water resistance but also improves the bag’s overall strength and aesthetic appeal.

Another method involves applying a polyethylene coating to the bag’s interior or exterior. This coating creates a smooth surface that repels water while maintaining the bag’s flexibility and usability.

Benefits Beyond Waterproofing

While the waterproof advantage is a key selling point, woven polypropylene bags offer several other benefits that make them a preferred choice in various sectors:

1. Durability: These bags can withstand rough handling, heavy loads, and exposure to harsh environments without compromising their integrity.

2. Lightweight: Despite their strength, woven polypropylene bags are lightweight, reducing transportation costs and making them easier to handle.

3. Cost-Effective: Compared to other packaging materials like jute or paper, polypropylene bags are more affordable while offering superior performance.

4. Customizability: Woven polypropylene bags can be customized in terms of size, color, printing, and design to meet specific branding or functional requirements.

5. Eco-Friendliness: Many manufacturers now produce recyclable woven polypropylene bags, contributing to sustainability efforts by reducing waste and promoting reuse.

Applications Across Industries

The versatility of woven polypropylene bags has led to their adoption across a diverse range of industries:

– Agriculture: Used for storing grains, seeds, fertilizers, animal feed, and produce.

– Construction: Ideal for packaging cement, sand, aggregates, and other building materials.

– Retail: Commonly used for packaging pet food, powdered goods, and bulk items.

– Logistics: Employed for transporting goods securely over long distances.

– Disaster Relief: Used as sandbags during floods or emergencies due to their water-resistant properties.

Challenges and Considerations

While woven polypropylene bags offer numerous advantages, there are some considerations to keep in mind:

1. UV Sensitivity: Prolonged exposure to sunlight can degrade polypropylene material. UV-stabilized variants are available to address this issue.

2. Environmental Impact: Although recyclable, improper disposal of polypropylene bags can contribute to plastic pollution. Encouraging recycling and reuse is critical to mitigating this impact.

3. Breathability vs. Waterproofing: Unlaminated woven polypropylene bags allow air circulation, which is beneficial for certain applications like storing fresh produce. However, achieving waterproofing through lamination reduces breathability. Choosing the right type of bag depends on the specific use case.

Woven polypropylene bags stand out as a practical and efficient solution for packaging and storage needs across industries. Their waterproof advantage, combined with durability, cost-effectiveness, and versatility, makes them an indispensable tool for businesses worldwide. As manufacturers continue to innovate with eco-friendly materials and advanced designs, these bags are poised to remain a cornerstone of modern packaging solutions.

By understanding the unique properties and applications of woven polypropylene bags, businesses can make informed decisions that enhance operational efficiency while protecting their products from environmental challenges. Whether it’s safeguarding agricultural produce from moisture or ensuring construction materials remain intact during transport, these bags deliver reliability and performance in every scenario.