Dry Bulk Container Liner

1.750.000 ₫ 1.550.000 ₫

| Place of Origin | VIETNAM |

|---|---|

| Brand Name | MINHANHPACK |

| Certification | SGS/CPTC |

| Model Number | MAP-20012024 |

| Minimum Order Quantity | 200pcs |

| Price | negotiation |

| Packaging Details | on pallets |

| Delivery Time | 35-45days |

| Supply Ability | 50K per month |

In the logistics and shipping industry, the efficient transportation of goods is a critical factor in ensuring supply chain success. For businesses dealing with dry bulk materials—such as grains, powders, granules, and other free-flowing commodities—maintaining product integrity during transit is paramount. This is where dry bulk container liners play a vital role. These innovative solutions are designed to optimize the transportation process, protect cargo, and enhance operational efficiency.

What is a Dry Bulk Container Liner?

A dry bulk container liner is a flexible, protective barrier installed inside standard shipping containers. Manufactured from high-strength polyethylene or polypropylene materials, these liners create a sealed environment within the container, allowing it to carry loose, dry bulk materials safely and efficiently. By transforming a standard contai ner into a specialized bulk carrier, liners eliminate the need for more expensive and less versatile transportation methods such as bulk tankers or specialized vessels.

ner into a specialized bulk carrier, liners eliminate the need for more expensive and less versatile transportation methods such as bulk tankers or specialized vessels.

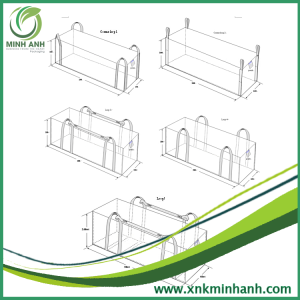

Dry bulk liners are available in various designs and sizes to suit different container types, including 20-foot and 40-foot containers. They are tailored to accommodate specific cargo requirements, ensuring optimal performance and safety during transit.

Key Features and Benefits of Dry Bulk Container Liners

Dry bulk container liners are an increasingly popular choice for industries such as agriculture, chemicals, mining, and food processing. Their widespread adoption can be attributed to the numerous benefits they offer:

1. Cost-Effectiveness

Using dry bulk liners allows businesses to maximize the use of standard shipping containers for bulk cargo transportation. This eliminates the need for dedicated bulk carriers, significantly reducing transportation costs. Additionally, liners minimize cleaning expenses by preventing cargo from coming into direct contact with the container walls.

2. Cargo Protection

One of the primary functions of a dry bulk liner is to safeguard the cargo from contamination, moisture, and external elements. The liner creates a sealed environment that prevents dust, dirt, and water from entering the container. This is especially critical for sensitive materials such as food-grade products or chemicals that require strict hygiene standards.

3. Ease of Loading and Unloading

Dry bulk liners are designed to facilitate efficient loading and unloading processes. Many liners feature spouts, hatches, or zipper systems that allow for seamless filling and discharge of materials. This reduces handling time and minimizes product loss during transit.

4. Versatility

Dry bulk liners can accommodate a wide range of materials, from fine powders like cement and flour to larger granules such as plastic pellets or grains. Their adaptability makes them suitable for diverse industries with varying transportation needs.

5. Environmental Sustainability

By using dry bulk liners, companies can reduce their reliance on single-use packaging materials such as sacks or bags. This not only lowers waste generation but also promotes sustainable practices within the supply chain.

Types of Dry Bulk Container Liners

To meet the diverse needs of different industries, dry bulk container liners are available in various configurations:

– Standard Liners: These are general-purpose liners suitable for most dry bulk materials.

– Barrier Liners: Designed for moisture-sensitive cargo, these liners provide an additional layer of protection against humidity and condensation.

– Antistatic Liners: Ideal for transporting materials prone to static electricity buildup, such as plastic resins or powders.

– Food-Grade Liners: Manufactured with FDA-approved materials, these liners ensure compliance with food safety regulations for edible products.

– Custom Liners: Tailored solutions designed to meet specific cargo requirements or container dimensions.

Applications of Dry Bulk Container Liners

Dry bulk container liners are used across a wide range of industries due to their versatility and reliability. Some common applications include:

– Agriculture: Transporting grains, seeds, animal feed, and fertilizers.

– Chemicals: Shipping powders, granules, and other chemical compounds.

– Food Industry: Moving flour, sugar, salt, coffee beans, and other dry food products.

– Mining: Transporting minerals such as coal, ores, and aggregates.

– Plastics: Carrying plastic pellets or resins used in manufacturing.

Installation and Handling

The installation of a dry bulk container liner requires careful planning to ensure optimal performance during transit. The process typically involves securing the liner to the container’s interior walls using hooks or adhesive strips. Once installed, the liner is ready for loading through designated openings or spouts.

Proper handling is essential to prevent damage to the liner during installation or while filling the container. Operators should follow manufacturer guidelines and use appropriate equipment to ensure a secure fit and prevent leaks or tears.

In today’s fast-paced global economy, the demand for efficient and cost-effective logistics solutions continues to grow. Dry bulk container liners have emerged as a reliable option for businesses seeking to transport loose, dry materials while maintaining product quality and minimizing costs.

With their numerous benefits—ranging from cargo protection to environmental sustainability—these liners have become an indispensable tool in industries worldwide. By investing in high-quality dry bulk container liners and adhering to best practices for their use, companies can achieve greater efficiency in their supply chains while safeguarding their valuable cargo.

As technology continues to advance, we can expect further innovations in dry bulk liner design, making them an even more integral part of modern logistics operations.

Hãy là người đầu tiên nhận xét “Dry Bulk Container Liner” Hủy

Sản phẩm tương tự

Bao Lót Containers

Bao Lót Containers

Bao Lót Containers

Bao Lót Containers

Bao Lót Containers

CPTC 40ft PP Sea Dry Bulk Container Liner For Coffee Beans Minerals

Bao Lót Containers

Bao Lót Containers

3 Cubic Meters Waste Agricultural Minerals Container Liner Bags

Đánh giá

Chưa có đánh giá nào.