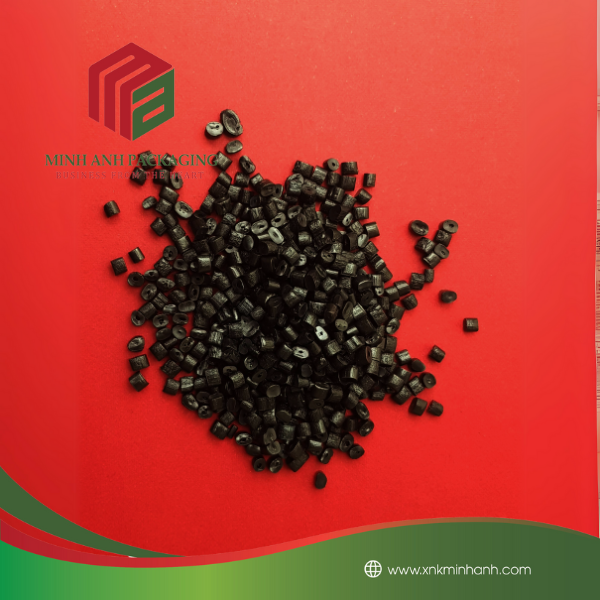

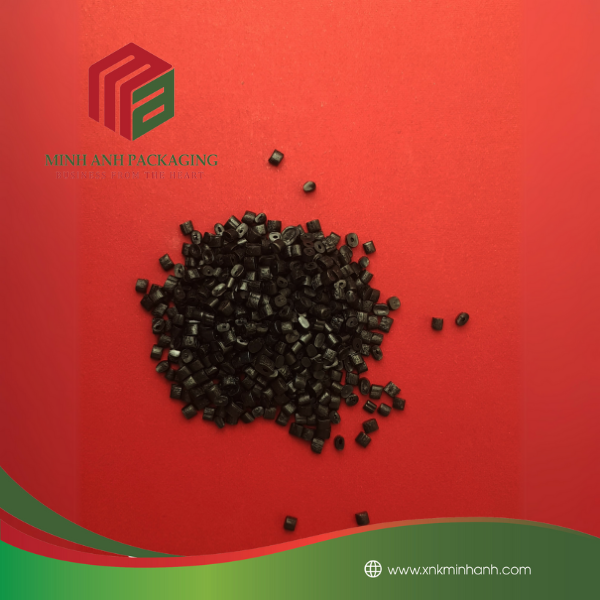

Understanding the Different Types of Plastic Granules

Plastic granules are a key component in the manufacturing of various plastic products. They are small, uniform particles of plastic material that are used as raw material in the production of plastic items. There are different types of plastic granules, each with its own unique properties and characteristics. Understanding the different types of plastic granules is essential for manufacturers and consumers alike. In this article, we will explore the various types of plastic granules and their uses.

Plastic granules are a key component in the manufacturing of various plastic products. They are small, uniform particles of plastic material that are used as raw material in the production of plastic items. There are different types of plastic granules, each with its own unique properties and characteristics. Understanding the different types of plastic granules is essential for manufacturers and consumers alike. In this article, we will explore the various types of plastic granules and their uses.

1. Polyethylene (PE) Granules:

Polyethylene is one of the most commonly used types of plastic. It is a versatile material that is used in the production of a wide range of products, including plastic bags, containers, and bottles. Polyethylene granules are known for their excellent chemical resistance, durability, and flexibility. They are also lightweight and have good impact strength, making them suitable for a variety of applications.

2. Polypropylene (PP) Granules:

Polypropylene is another popular type of plastic that is widely used in the manufacturing industry. PP granules are known for their high melting point, which makes them suitable for applications that require heat resistance. They are also known for their excellent chemical resistance and stiffness, making them ideal for the production of automotive parts, packaging materials, and household products.

3. Polyvinyl Chloride (PVC) Granules:

PVC is a widely used thermoplastic material that is known for its excellent chemical resistance and fire-retardant properties. PVC granules are commonly used in the production of pipes, fittings, profiles, and cables. They are also used in the construction industry for various applications, including window frames, flooring, and roofing materials.

4. Polystyrene (PS) Granules:

Polystyrene is a versatile plastic material that is known for its excellent insulation properties and transparency. PS granules are commonly used in the production of food packaging, disposable cutlery, and insulation materials. They are also used in the manufacturing of consumer electronics and household appliances.

5. Acrylonitrile Butadiene Styrene (ABS) Granules:

ABS is a tough and rigid thermoplastic material that is known for its high impact resistance and heat resistance. ABS granules are commonly used in the automotive industry for the production of car parts, as well as in the manufacturing of consumer goods such as luggage, toys, and electronic housings.

6. Polycarbonate (PC) Granules:

Polycarbonate is a transparent thermoplastic material that is known for its high impact resistance and optical clarity. PC granules are commonly used in the production of compact discs, eyewear lenses, and safety helmets. They are also used in the automotive industry for the production of headlamp lenses and interior trims.

In conclusion, plastic granules come in various types, each with its own unique properties and characteristics. Understanding the different types of plastic granules is essential for manufacturers to choose the right material for their specific applications. Additionally, consumers can benefit from knowing the type of plastic used in the products they purchase. With a better understanding of plastic granules, both manufacturers and consumers can make informed decisions about the materials they use and the products they buy.

Hãy là người đầu tiên nhận xét “Understanding the Different Types of Plastic Granules” Hủy

Sản phẩm tương tự

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Đánh giá

Chưa có đánh giá nào.