Innovations in Plastic Granules Production

Another important innovation in plastic granules production is the incorporation of recycled plastic materials. With the growing emphasis on sustainability and environmental responsibility, many manufacturers have started using recycled plastics as raw materials for granule production. This not only helps reduce the amount of plastic waste ending up in landfills but also conserves natural resources by decreasing the reliance on virgin plastics. Innovations in recycling technologies, such as advanced sorting and cleaning processes, have made it possible to produce high-quality plastic granules from recycled materials, further contributing to a more sustainable plastic manufacturing industry.

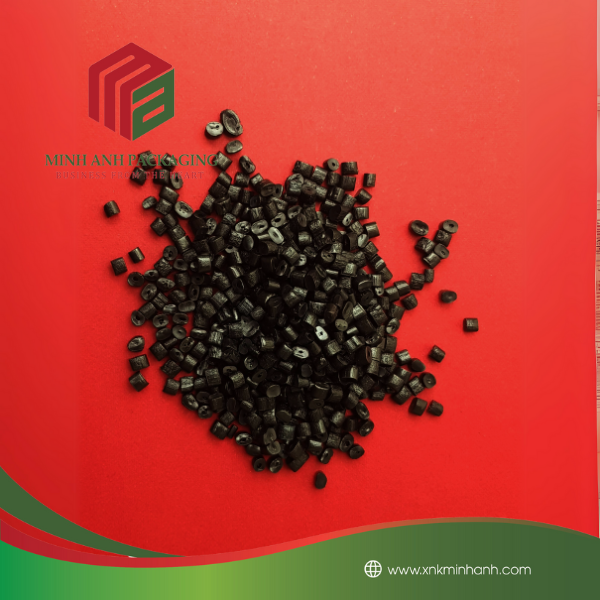

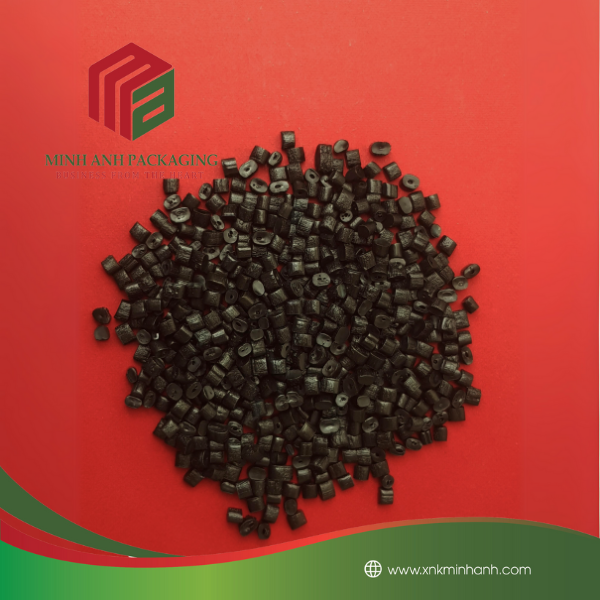

Plastic granules, also known as plastic pellets, are small, cylindrical particles used in the manufacturing of various plastic products. These granules are typically produced through a process called plastic extrusion, where raw plastic material is melted and formed into a continuous shape before being cut into granules of the desired size. Over the years, there have been significant innovations in the production of plastic granules, leading to improved efficiency, quality, and sustainability in the plastic manufacturing industry.

One of the key innovations in plastic granules production is the development of advanced extrusion technology. Traditional extrusion processes often resulted in inconsistent granule sizes and shapes, leading to challenges in downstream processing and product quality. However, advancements in extrusion machinery, such as improved screw designs, temperature control systems, and die technology, have enabled manufacturers to produce more uniform and high-quality plastic granules. This not only enhances the performance of the end products but also reduces waste and improves overall production efficiency.

Another important innovation in plastic granules production is the incorporation of recycled plastic materials. With the growing emphasis on sustainability and environmental responsibility, many manufacturers have started using recycled plastics as raw materials for granule production. This not only helps reduce the amount of plastic waste ending up in landfills but also conserves natural resources by decreasing the reliance on virgin plastics. Innovations in recycling technologies, such as advanced sorting and cleaning processes, have made it possible to produce high-quality plastic granules from recycled materials, further contributing to a more sustainable plastic manufacturing industry.

In addition to using recycled materials, there have been advancements in the development of biodegradable and compostable plastic granules. These innovative materials are designed to break down naturally over time, reducing their impact on the environment compared to traditional plastics. Manufacturers have been investing in research and development to create biodegradable and compostable plastic granules that meet the required performance and durability standards for various applications. These innovations offer a promising solution for reducing plastic pollution and addressing the environmental concerns associated with plastic waste.

Furthermore, advancements in additive technologies have played a significant role in improving the properties of plastic granules. Additives such as colorants, UV stabilizers, flame retardants, and impact modifiers can be incorporated into the granules during the production process to enhance their performance and durability. Innovations in additive manufacturing have led to the development of custom formulations tailored to specific end-use applications, allowing manufacturers to meet diverse customer requirements and industry standards. This level of customization has expanded the potential applications of plastic granules across various sectors, including automotive, construction, packaging, and consumer goods.

Moreover, digitalization and automation have revolutionized the production processes of plastic granules. Advanced control systems, real-time monitoring technologies, and data analytics tools have enabled manufacturers to optimize their production lines for improved efficiency and quality. Automation of material handling, blending, and packaging operations has also reduced human intervention and minimized errors, leading to more consistent and reliable granule production. The integration of digital technologies has not only streamlined operations but also provided valuable insights for continuous process improvement and predictive maintenance.

In conclusion, innovations in plastic granules production have significantly transformed the plastic manufacturing industry, driving improvements in efficiency, quality, and sustainability. From advanced extrusion technologies to the use of recycled materials and the development of biodegradable options, manufacturers are constantly pushing the boundaries to meet the evolving demands of a more environmentally conscious market. With ongoing research and development efforts focused on additive technologies, digitalization, and automation, the future of plastic granules production holds promising prospects for further enhancing the performance and environmental footprint of plastic products.

Hãy là người đầu tiên nhận xét “Innovations in Plastic Granules Production” Hủy

Sản phẩm tương tự

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Bao Jumbo

Đánh giá

Chưa có đánh giá nào.