Choosing the Right FIBC Bag for Your Industry Needs

When it comes to choosing the right FIBC (Flexible Intermediate Bulk Container) bag for your industry needs, there are several factors to consider. FIBC bags, also known as bulk bags, big bags, or jumbo bags, are used in a wide range of industries for the transportation and storage of dry bulk materials such as sand, gravel, chemicals, food products, and more. Selecting the right FIBC bag for your specific industry requirements is crucial to ensuring the safe and efficient handling of your materials.

When it comes to choosing the right FIBC (Flexible Intermediate Bulk Container) bag for your industry needs, there are several factors to consider. FIBC bags, also known as bulk bags, big bags, or jumbo bags, are used in a wide range of industries for the transportation and storage of dry bulk materials such as sand, gravel, chemicals, food products, and more. Selecting the right FIBC bag for your specific industry requirements is crucial to ensuring the safe and efficient handling of your materials.

One of the first considerations when choosing an FIBC bag is the type of material that will be transported or stored in the bag. Different materials have different characteristics and may require specific types of FIBC bags to ensure safe containment and handling. For example, food-grade materials will require FIBC bags that meet strict hygiene and safety standards, while hazardous materials may require FIBC bags with specialized features such as anti-static properties or barrier films to prevent contamination or leakage.

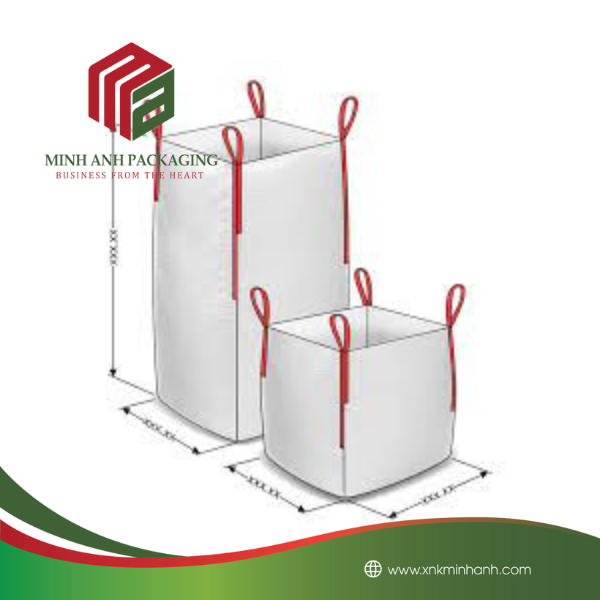

In addition to the type of material being handled, the weight and volume of the material are also important factors to consider when selecting an FIBC bag. FIBC bags come in a variety of sizes and weight capacities, so it’s essential to choose a bag that can safely accommodate the specific weight and volume of your materials. Overfilling or underfilling an FIBC bag can compromise its integrity and lead to safety hazards during transportation and handling.

The design and construction of an FIBC bag are also critical considerations. Different industries may require specific features such as sift-proof seams, UV protection, or liners to meet their unique needs. For example, the construction of an FIBC bag used for the transportation of fine powders will differ from one used for the storage of bulky materials. Understanding the specific requirements of your industry will help you select an FIBC bag with the appropriate design and construction features.

Another important factor to consider when choosing an FIBC bag is the method of handling and transportation. Some industries may require FIBC bags with lifting loops for crane or forklift handling, while others may need bags with spouts for easy filling and discharge. The type of handling and transportation equipment used in your industry will influence the design and features required in an FIBC bag.

Regulatory compliance is also a crucial consideration when selecting an FIBC bag for your industry needs. Depending on the industry and the materials being handled, there may be specific regulations and standards that govern the use of FIBC bags. It’s essential to ensure that the FIBC bags you choose meet all relevant regulatory requirements to avoid any compliance issues or safety risks.

Finally, cost considerations are always a factor in selecting the right FIBC bag for your industry needs. While it’s important to choose a bag that meets all necessary requirements, it’s also essential to find a cost-effective solution that fits within your budget. Working with a reputable FIBC bag supplier can help you find a balance between quality and cost to ensure that you get the best value for your investment.

In conclusion, choosing the right FIBC bag for your industry needs requires careful consideration of the type of material, weight and volume requirements, design and construction features, handling and transportation methods, regulatory compliance, and cost considerations. By understanding the specific requirements of your industry and working with a knowledgeable FIBC bag supplier, you can select an FIBC bag that meets all your needs for safe and efficient material handling.

Hãy là người đầu tiên nhận xét “Choosing the Right FIBC Bag for Your Industry Needs” Hủy

Sản phẩm tương tự

Tin Tức Bao Bì

Tin Tức Bao Bì

Tin Tức Bao Bì

Tin Tức Bao Bì

Tin Tức Bao Bì

Tin Tức Bao Bì

Đánh giá

Chưa có đánh giá nào.